Assemblies

Assemblies

Early and intense for the best results

With the early, intensive examination of every task, we kill several birds with one stone: by the exact analysis of submitted drawings and the detailed coordination, we eliminate sources of error for the further course of the project. The functionality and the precision are thus ensured early on, and thus it saves time and costs. It helps that all steps are monitored and accompanied by the same project manager.

Some examples of assemblies manufactured by C-Technik:

- cutting scaffoldings

- roll change system

- decoiler

- reversing reel

- coiler

- coil transportation systems

- coil storage systems

- spare parts

- ...

Products

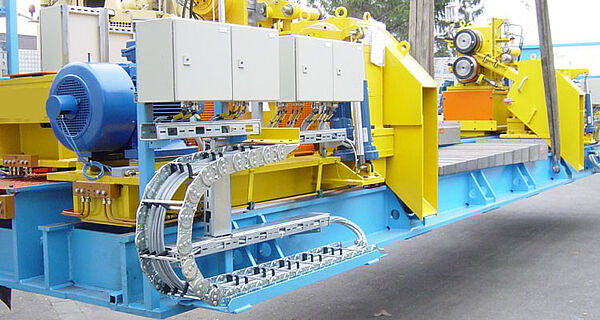

Coiler group for tailored blank material

- movable assemblies due to constant change of plant center

- oscillatory winding possible

- four-jaw take-up head with two hydraulic clamps

- clamp segments with thickness adaptation, the band is different in thickness on the width

- automatic tape threading

- brake rollers with inclination and pressure adjustment and extension device

- band side guidance

- punch with tool as a quick-change system

Technical data:

- speed 50 m/min

- coil weight 30.000 kg

- coil outside Ø 600 – 2.000 mm

- coil inside Ø 508/610 mm

- strip width 100 – 2.200 mm

- strip thickness 0,5 – 4,5 mm

- center system movable (1.750 mm)

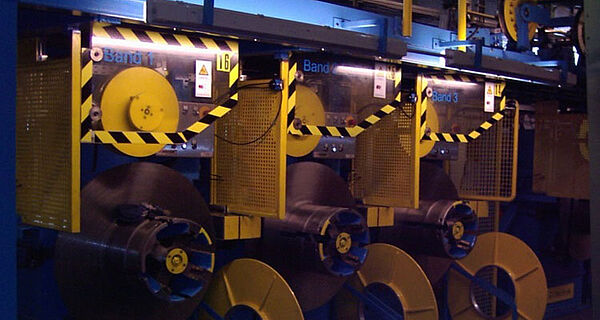

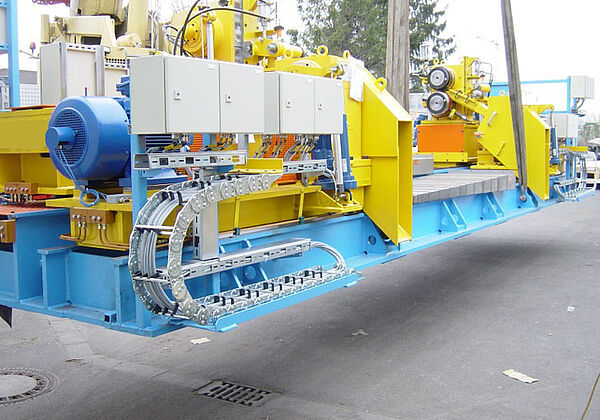

Laying coiler and unwind section

An existing system was expanded by four laying winder and four unwinding stations. At the same time, the carrying capacity and laying width of the new laying winder were increased.

Technical data:

- speed 150 m/min

- pack weight 1.000 kg

- pack outside Ø 1.000 mm

- laying width 190/305 mm

- single strip width 8 – 32 mm

- strip thickness 0,6 – 1,2 mm

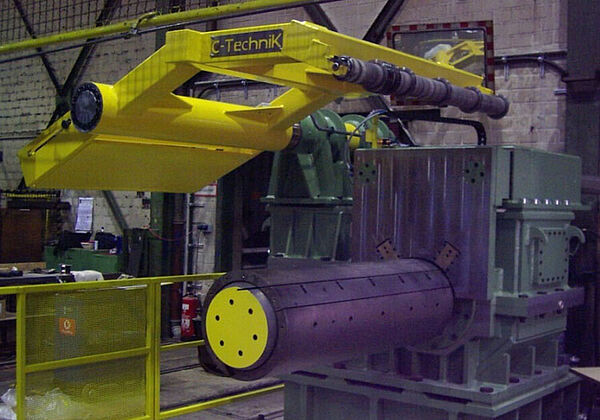

Rolling stand with leveler

In front of a press, a profiling roll stand with a 7-roll straightener was installed. The rolling stand can use different rolling sleeves to roll the strip edges with different profiles. In the leveler drive rollers are additionally installed.

Technical data:

- speed 120 m/min

- strip width 150 mm

- strip thickness 0,5 – 4 mm

- rolling force 300KN

- 7-roller leveler

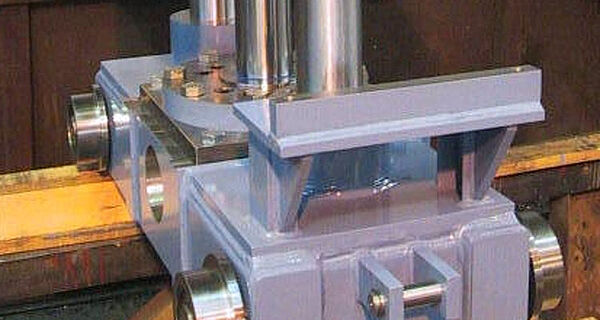

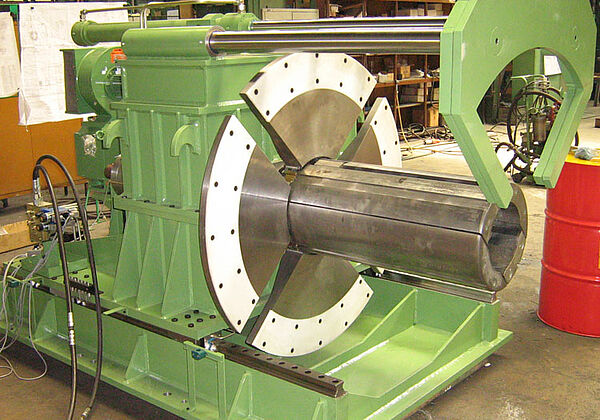

Coil transport wagon (CTW)

Self-supporting reel shaft with a spreading range from Ø 525 to Ø 615 mm!

Functions:

- drive forward - back

lifting - lowering, stroke 600 mm

turn off - on

rider roles above and below

Technical data:

- speed 15 m/min

- coil weight 45.000 kg

- coil outside Ø 2.200 mm

- strip width 2.080 mm

- complete weight incl. ring 100t

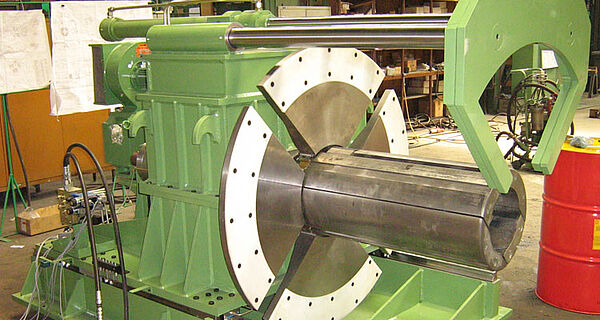

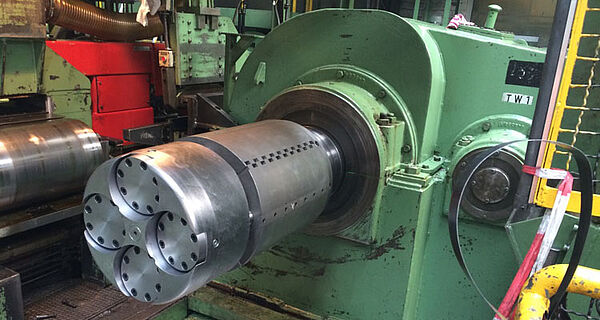

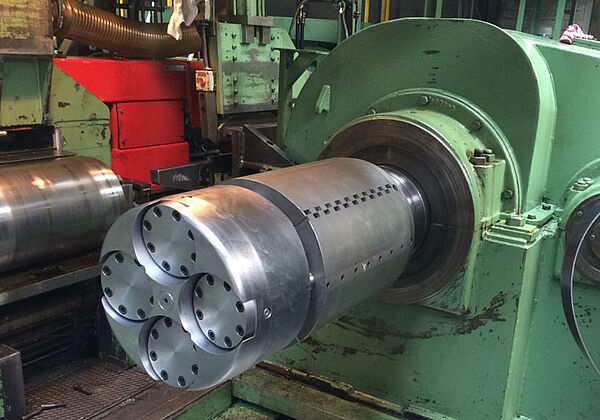

Refurbishment of reverse reel shafts

Both reverse reel shafts of a MKW rolling mill stand (SMS Bj. 1981) were replaced, including the expanding clamping cylinder and rotating oil supply with new, with a different design.

Technical data:

- speed 600 m/min

- coil weight 10.000 kg

- coil outside Ø 1.850 mm

- coil inside Ø 500 mm

- strip width 520 mm

- strip thickness 0,5 – 3,0 mm